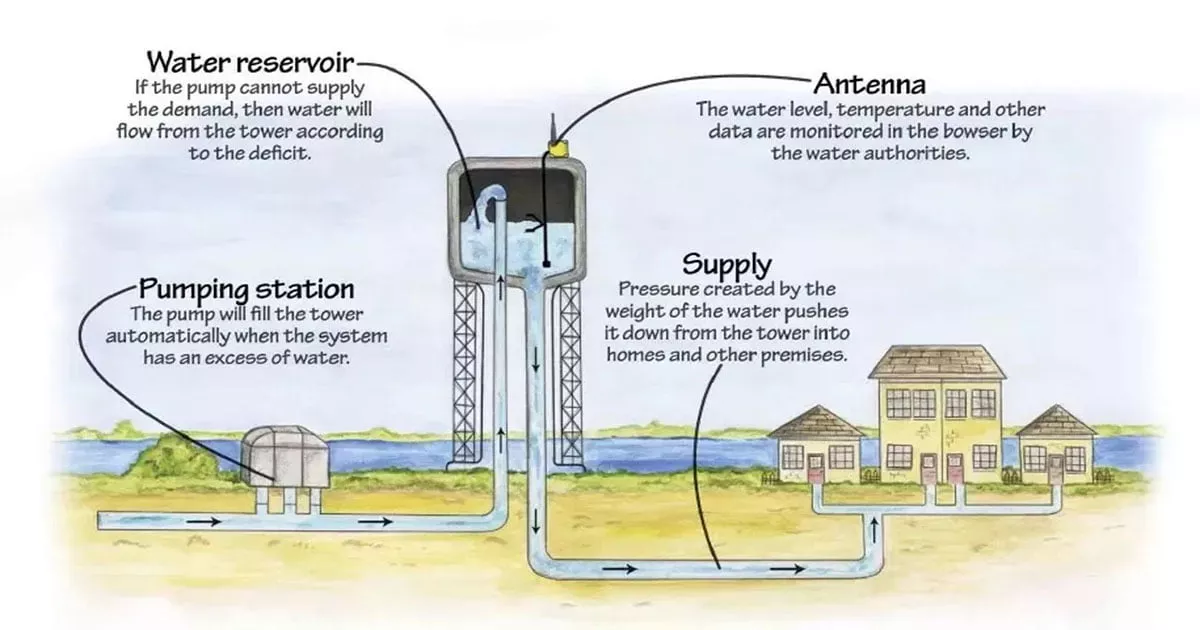

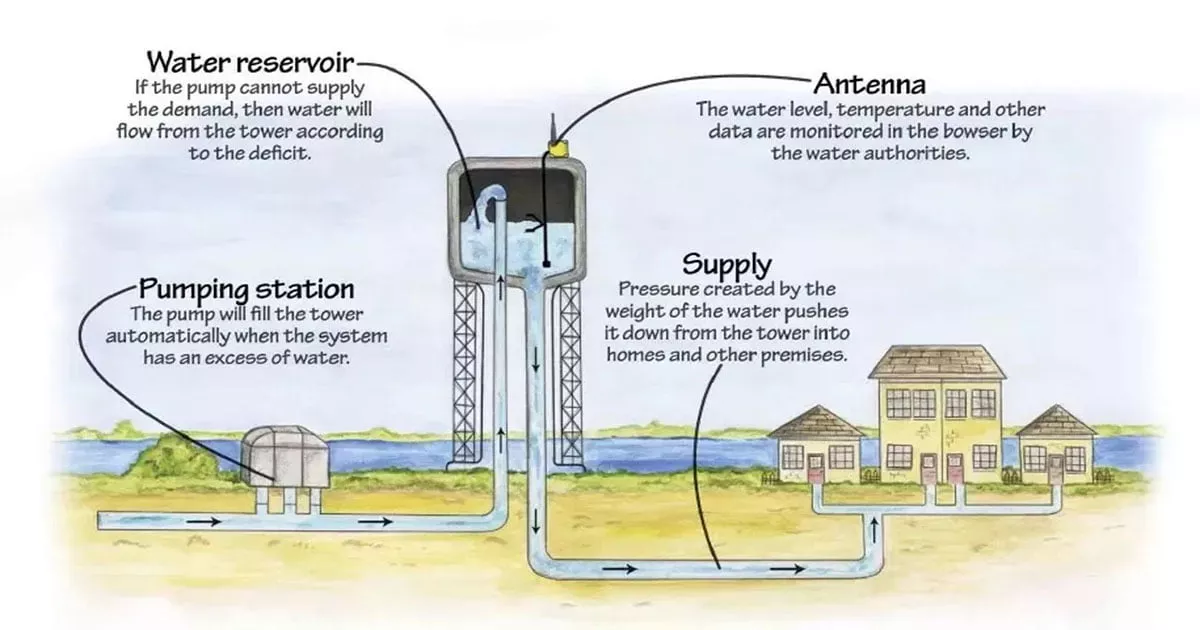

Water towers are a common sight, towering over communities, but how do they actually work, and why are they so important? Knowing how they function helps us appreciate the critical role they play in maintaining water pressure and storing water for everyday use and emergencies.

Water towers offer a simple, low-tech solution for creating reliable water pressure. By elevating water, they harness gravity to maintain steady pressure for homes, businesses, and public services—without relying on constantly running pumps. Since there are few moving parts, water towers provide consistent, 24-hour water pressure with minimal risk of failure. Without them, utilities would need costly, always-on pumps to meet fluctuating demand, which would be neither economical nor practical.

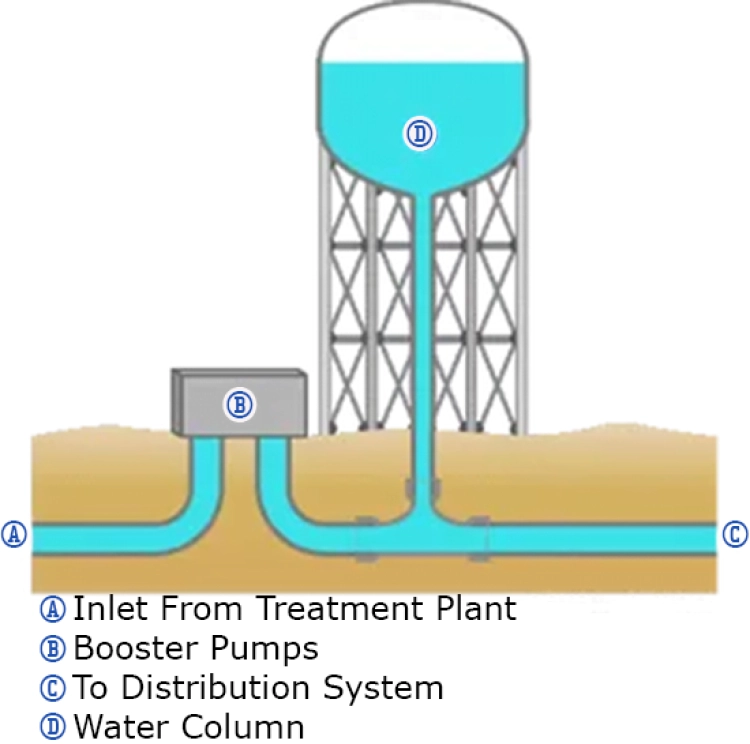

The reason water is pumped into the air is all about pressure. Every 2.31 feet of elevation creates 1 psi (pound per square inch) of water pressure. The size of the water column doesn’t matter—it could be as narrow as a straw or as wide as 20 feet; what counts is the height. For example, if a water tower is 140 feet tall, it will generate approximately 60 psi of pressure (140 ÷ 2.31 = 60.61 psi). In metric, this equals about 0.433 psi per meter.

Most water systems operate between 30 and 80 psi, with the ideal range being 60 to 70 psi, depending on the height of the water tower relative to your faucet. The primary reason towers are elevated is to create this pressure. But why not just pump water into a tall, narrow pipe? Why have a large tank at the top?

The large tank at the top of a water tower plays a vital role in storing water, reducing the need for continuous pump operation. This stored water ensures a steady supply, even during power outages, for several hours or up to a full day. Without the tank, water would stop flowing as soon as the pump shuts off. The tank allows for greater water volume, meaning booster pumps only need to run long enough to refill it before gravity takes over to supply water.

Water tower storage also serves as an emergency backup. In the event of a power failure, the stored water provides a reliable supply to homes and businesses. Most municipalities store at least 24 hours' worth of water in their towers. The size of the tank depends on the number of customers it serves—larger communities require more water storage capacity to meet demand.

Water towers are essential for fire protection, ensuring there’s enough water stored for emergencies. Fire trucks, especially pumper trucks, can quickly drain a water system. During a large fire, multiple trucks drawing water from hydrants could deplete the supply faster than pumps can refill it. The water stored in the tower helps meet this demand, maintaining pressure and providing enough water to support firefighting, even when demand surges.

The diagram above shows a FIFO (First In, First Out) model. In a FIFO setup, the first bit of water to enter the tank (typically at the bottom) is the first to leave. This configuration can lead to stagnant water accumulating at the top of the tank, as the newly added water is constantly pushed through first. Although it maintains system pressure, if the tank level drops significantly, the stagnant water at the top will enter the distribution system, which can affect water quality.

FILO (First In, Last Out) water towers operate differently. In a FILO configuration, the first water to enter the tank (usually from the top) is the last to leave. This is achieved by using a specialized piping system that draws water from the base of the tank. FILO systems are better at keeping older water at the top of the tank and reduce the risk of that water being pushed into the distribution system. However, if the water is not circulated or mixed, it can still become stagnant over time.

Mixed Water Towers do as the name suggests—they actively mix the water inside the tank to prevent stagnation. This method is commonly used to retrofit older water towers with only one standpipe. Mixing is typically achieved by installing an agitator or a circulation pump within the tank, ensuring that water is continually circulated and refreshed. This approach combines the advantages of both FILO and FIFO setups by maintaining pressure while also ensuring that water quality is not compromised due to stagnation.

Detention time, also known as contact time, is a critical concept in water treatment that ensures disinfectants like chlorine have sufficient time to react with and neutralize pathogens before the water is delivered to consumers. The idea is to maintain a specific concentration of chlorine in the water for a designated period, ensuring that bacteria, viruses, and other harmful microorganisms are effectively killed or rendered inactive. This process is essential for ensuring water safety and quality, as inadequate detention time can lead to the presence of harmful contaminants in the water supply.

Water towers serve as a key component in providing the necessary detention time. As water is stored in the tower, the contact time allows chlorine to distribute evenly and reach all parts of the water. During this period, the chlorine has time to interact with potential contaminants, ensuring that the water is disinfected thoroughly. Detention time is measured by evaluating the flow dynamics of water within the tower, with the goal of achieving effective chlorine contact with 90% of the water before it is released into the distribution system.

According to the EPA, the minimum detention time needed for effective disinfection can vary, but in most cases, it is around 30 minutes at the required chlorine concentration. This duration is based on the time it takes for 90% of the water to come into contact with the chlorine (T10 time) before it flows into the distribution system(US EPA). Proper mixing and adequate detention time are critical for maintaining safe drinking water quality and meeting regulatory standards(NC.gov).

Have you ever tried blowing into a straw while covering one end with your finger? It doesn’t work because the air has nowhere to go. The same principle applies to water towers—without vents, the tank wouldn’t function properly. Vents allow air to escape as water fills the tank and re-enter as the water level drops, preventing a vacuum that could collapse the structure.

However, exposing water to open air brings its own challenges. To protect the water, a fine mesh is installed over the vent openings to keep out insects and birds. These vents are typically angled downward to prevent rain from entering and to keep birds from contaminating the water.

Overflows play a key role in preventing damage to water towers. If pump controls malfunction, excess water could be forced out of the vent at the top, potentially damaging the mesh screen or vent housing. To avoid this, an overflow pipe located just below the vent allows water to escape safely. This pipe also lets operators occasionally overfill the tank to flush out floating debris or stagnant water, which is especially useful in systems with a LIFO setup.

The paint on a water tower is crucial for its protection. If the exterior paint becomes too thin, rust can form quickly. The paint acts as a barrier, shielding the metal from exposure to elements like chlorinated water. Even a small chip in the interior coating can lead to rapid rusting, as metal and chlorine don’t mix well.

Regular cleaning is also essential for maintaining water quality and the tank's longevity. Over time, iron and sand particles from the treatment process can accumulate inside the tank. While these sediments aren’t harmful, they can make the water appear cloudy. Ideally, water towers should be cleaned annually, but they should never go more than five years without maintenance.

Repainting is one of the most expensive parts of water tower upkeep. From my experience working with small municipalities, it can be challenging to budget for, but it’s a necessary expense to ensure the tower remains in good condition and continues to function properly.

Forty years ago, it wasn’t unusual to see teenagers climbing water towers, and some even swam in the tanks. Today, security around water towers is much stricter. No one wants someone tampering with their drinking water, and municipalities have responded by installing ladder guards and fences around most water facilities.

After 9/11, concerns about terrorism heightened the need to secure public water supplies. As a result, laws like the USA PATRIOT Act and the Critical Infrastructure Protection Act now make it a felony to trespass or interfere with public works, including water towers. Federal statutes such as 18 U.S. Code § 1361 also criminalize damage to public property, ensuring strict penalties for anyone attempting to disrupt critical infrastructure.

If you came here curious about how water towers work, I hope you now have a better understanding of their inner workings. The next time you pass one, take a moment to appreciate the marvel of engineering they represent. Often blending into the background due to their familiarity, water towers are silent workhorses, supporting the growth of our communities and ensuring reliable access to water. That’s how water towers quietly keep society running.

1. What does a water tower do?

A water tower acts as a storage tank for treated water, ensuring consistent water pressure for homes, businesses, and industries. It uses the force of gravity to provide enough pressure to deliver water through the distribution system. Beyond just maintaining pressure, the water tower also serves as a reserve for emergency situations, such as during power outages or high-demand scenarios like firefighting. Municipalities often store enough water in the tower to supply the community for 24 hours.

2. Why are water towers in the air?

The elevation of a water tower is key to its function. For every 2.31 feet of height, the water exerts 1 psi (pounds per square inch) of pressure. By positioning the tower high above the ground, usually between 100 and 200 feet, the system creates enough water pressure to serve the surrounding area without the need for constant pumping. This design minimizes energy consumption and reduces the need for mechanical parts that could fail. Without the height, municipalities would need to rely on expensive, always-on pumps, which is far less economical.

3. How does a water tower work?

A water tower works by holding water at a high elevation. When water is pumped into the tower's tank, it is stored until needed. As water is drawn from the distribution system (e.g., through faucets, showers, or hydrants), gravity pulls the water from the tower, ensuring a steady flow and pressure. The height of the tower dictates how much pressure is exerted, and this pressure is sufficient to supply water to buildings and homes without the need for continuous pumping. The tower's storage also helps in emergencies, such as fires, when large amounts of water may be needed quickly.

4. How much water can a typical water tower hold?

Water towers come in many sizes, depending on the needs of the community they serve. Small-town towers might hold 50,000 to 100,000 gallons, while large urban towers can store upwards of several million gallons. For example, a small residential water tower might only be needed to hold 200,000 gallons, but in areas with high water demands—such as industrial zones or large cities—the tower may hold 5 million gallons or more. Towers are designed to provide enough storage for a 24-hour supply, ensuring a backup in case of power outages or emergencies.

5. How often do water towers need maintenance?

Routine maintenance is essential to ensure water quality and structural integrity. Water towers should be inspected annually for any signs of rust, wear, or damage to the paint that protects the metal structure. Cleaning is recommended every 1 to 5 years to remove sediment like sand or iron that may accumulate in the tank. Any rust or paint deterioration on the interior or exterior of the tank can lead to structural weakness and contamination, so timely repainting is crucial. Without proper maintenance, the tank can degrade quickly, especially due to the presence of chlorinated water, which accelerates rust.

6. How do water towers help during emergencies?

In the event of a power outage, the water stored in the tower provides an uninterrupted supply for several hours or even a full day, depending on the tower's size. This is crucial for firefighting efforts, as fire hydrants draw directly from the water distribution system. In emergencies, such as large fires, the reserve water in the tower ensures that the system can meet sudden spikes in demand, helping firefighters maintain consistent access to water.

7. What prevents water towers from collapsing under the pressure?

Water towers are designed with vents and overflow systems to prevent pressure from damaging the structure. Vents allow air to enter and exit the tank as water levels rise and fall, preventing a vacuum from forming inside. Overflow pipes ensure that excess water has a safe exit if the tank is overfilled. Without these safety measures, the pressure from the water or air could cause the tank to collapse or damage the structure.

8. What keeps the water in the tower clean?

Water towers are sealed, but they also need vents to prevent air pressure issues. To keep the water clean, fine mesh screens cover these vents, preventing debris, bugs, birds, and other contaminants from entering the tank. Regular inspections and cleanings are vital to ensuring that the mesh is intact and the water remains uncontaminated. Many municipalities also treat the water with chlorine to kill any potential bacteria or viruses.

9. Why are water towers painted?

The paint on a water tower isn’t just for looks. It plays an essential role in protecting the metal structure from corrosion. The exterior paint shields the metal from rust caused by exposure to the elements, while the interior paint prevents rust from forming inside the tank, where it comes into contact with chlorinated water. Maintaining the paint is critical, as rust can weaken the structure and potentially contaminate the water supply. Repainting is one of the most significant maintenance expenses for water towers, but it’s necessary to keep the structure in working order.

10. Are water towers secure?

Yes, water towers are much more secure today than they used to be. Many older towers were open for anyone to climb, and there are stories of people swimming in the tanks. Today, climbing a water tower without permission is a felony, and most are equipped with ladder guards and fences to prevent unauthorized access. Since 9/11, security measures have been increased to prevent any threats to public water supplies.